Artificial Marble tub

Artificial Marble tub, originated in Italy, because of its manufacturing process known as the casting cylinder or hand cylinder. Artificial Marble tub, is a kind of bathtub, bathroom industry is the new darling, but also following the steam room after another bathroom luxury.

Artificial Marble tub because of its set of a variety of advantages in one, is to abandon the acrylic bathtub, ceramic cylinder and cast iron cylinder and the emergence of the lack of the latest bath, is the trend and high quality representatives. Because of its high level of the requirements of the process, and now the domestic mass production of artificial Marble tub manufacturers are not too much.

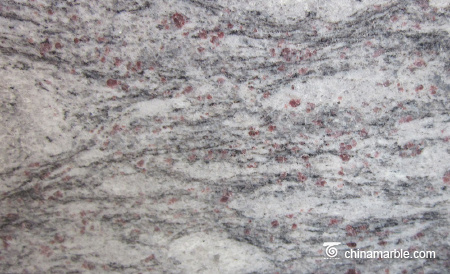

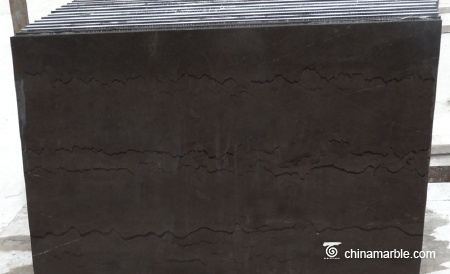

Artificial Marble tub is made of environmentally friendly transparent resin, glass beads and baromole powder and other other materials through mixing, casting, splicing, carefully polished. At the same time in the production process can be deployed in different colors, so that it has a different aesthetic appearance.

The appearance of the product is simple, elegant and generous, the surface finish is high, the heat transfer coefficient is small, the heat preservation performance is good, the strength is high and the toughness is good, the anti-engraving pressure, the abrasion resistance is strong, the mold is resistant to antibacterial, the high temperature is difficult to be stained, , Easy to repair, the weight is only ordinary artificial Marble tub 65%.

Artificial Marble tub wall thickness is generally about 2.5CM, there are curvature of the place will be thin about 2MM.

Artificial Marble tub surface smooth as porcelain, weighs about 150 kg, so the packaging will be particularly careful. The first is to use thick Zhenzhu Mian to protect the cylinder along; then in the cylinder outside the package of two transparent film; then followed by steel banding; and then use the carton to do external sealing, and finally with the wooden strip of real packing, Free to put no worries.

The development direction of the world bathtub is to simplify and the overall development of China's early 90s glass fiber reinforced plastic bathtub is the simplest single cylinder, the middle of the emergence of acrylic and cast iron cylinder. Cast iron cylinder processing difficult, bulky, no insulation; acrylic processing convenient, lightweight, heat insulation, so the wind around the world, while the acrylic molding process a lot worse.

In the industry in order to enhance the competitiveness of enterprises to change the appearance of the product and promote the development of enterprises, to around 2003, minimalism to the market, thus forming a branch of the bathtub, the classic cylinder, and now the acrylic bathtub through ten years Around the development, has reached its peak, it is difficult to have a big breakthrough.

Acrylic bathtub has the biggest drawback is more than 95% of the cylinder and skirt to be separated, thus undermining the integrity of the bathtub and the fluency of the line, feeling imperfect. So the artificial stone overall bath turned out to overcome the acrylic and cast iron cylinder of many deficiencies, conform to the trend of the times and the direction of development, it will replace the acrylic and cast iron cylinder into a stylish high-end bathtub, and acrylic products will eventually be reduced to middle and low product.

Hot Products